Marvelous Info About Can You Fix A Damaged PCB

The Burning Question

1. Assessing the Damage

So, your Printed Circuit Board (PCB) took a tumble, suffered a surge, or maybe just decided to give up the ghost. The big question now swirling around in your head is: "Can I actually fix this thing?" Well, the answer, like most things in life, isn't a simple yes or no. It depends. It hinges on the extent of the damage, your level of expertise (are you a seasoned electrical engineer or a curious hobbyist?), and the tools you have at your disposal. Think of it like a broken vase — a tiny chip? Maybe you can glue it. Shattered into a million pieces? Time for a new vase.

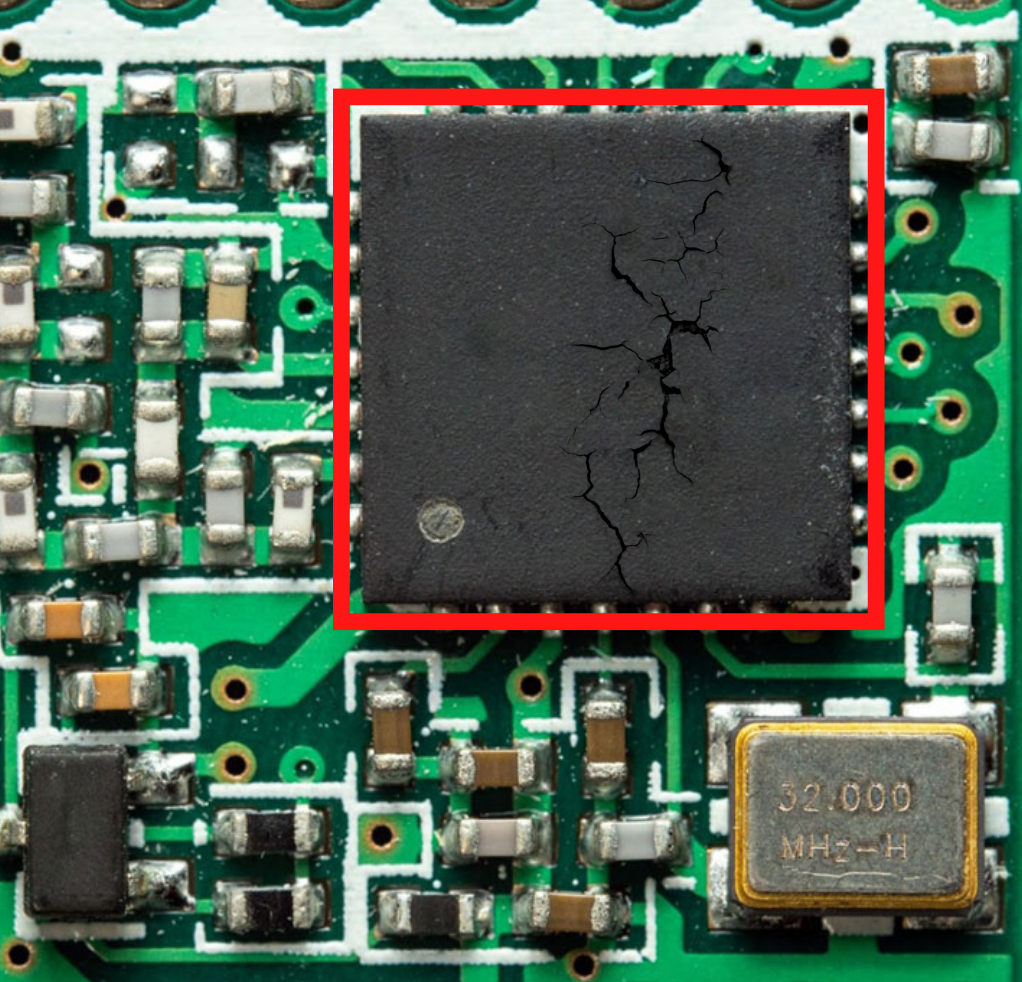

First, take a good hard look at the PCB. Are we talking about a cracked board, burnt components, lifted pads, or just some corroded traces? Each type of damage presents its own unique challenges and requires a different approach. A visual inspection is crucial. Use a magnifying glass or even a microscope if you have one. This will help you identify hairline cracks, cold solder joints, and other subtle issues that might not be immediately obvious to the naked eye. Think of yourself as a PCB detective, searching for clues!

Consider the value of the device the PCB is in. Is it a crucial piece of equipment that would cost a fortune to replace, or a cheap gadget you picked up at a flea market? The cost of repair should always be weighed against the cost of replacement. Sometimes, the time and effort required to fix a damaged PCB simply aren't worth it, especially if you factor in the risk of causing further damage. Knowing when to throw in the towel is a valuable skill in itself.

Also, take into account the availability of replacement parts. If you need a specific IC or connector that's no longer manufactured, you might be out of luck. Scouring online marketplaces and electronic component suppliers can sometimes yield results, but it's not always a guarantee. The "hunt for parts" can sometimes be more time-consuming than the actual repair itself. Consider the documentation of the board, if it available it will be a plus for the repair.

Corrosion PCB What Causes Corrosion, And How Can You, 60 OFF

Types of PCB Damage and Potential Fixes

2. Surface-Level Scratches and Minor Trace Damage

Okay, so you've determined the damage isn't catastrophic. Maybe it's just a scratch on the surface or a break in a single trace. These are generally the easiest to fix. For scratches, you might not even need to do anything, especially if they don't expose any copper. For broken traces, a simple solder bridge or the use of a thin wire to create a jumper can often do the trick. Just make sure to clean the area thoroughly before applying any solder.

Think of repairing traces like performing a tiny surgery. Precision is key! Use a fine-tipped soldering iron and high-quality solder. Avoid applying too much heat, as this can further damage the board or lift the trace entirely. If you're using a wire jumper, make sure it's properly insulated to prevent short circuits. Heat shrink tubing is your best friend here.

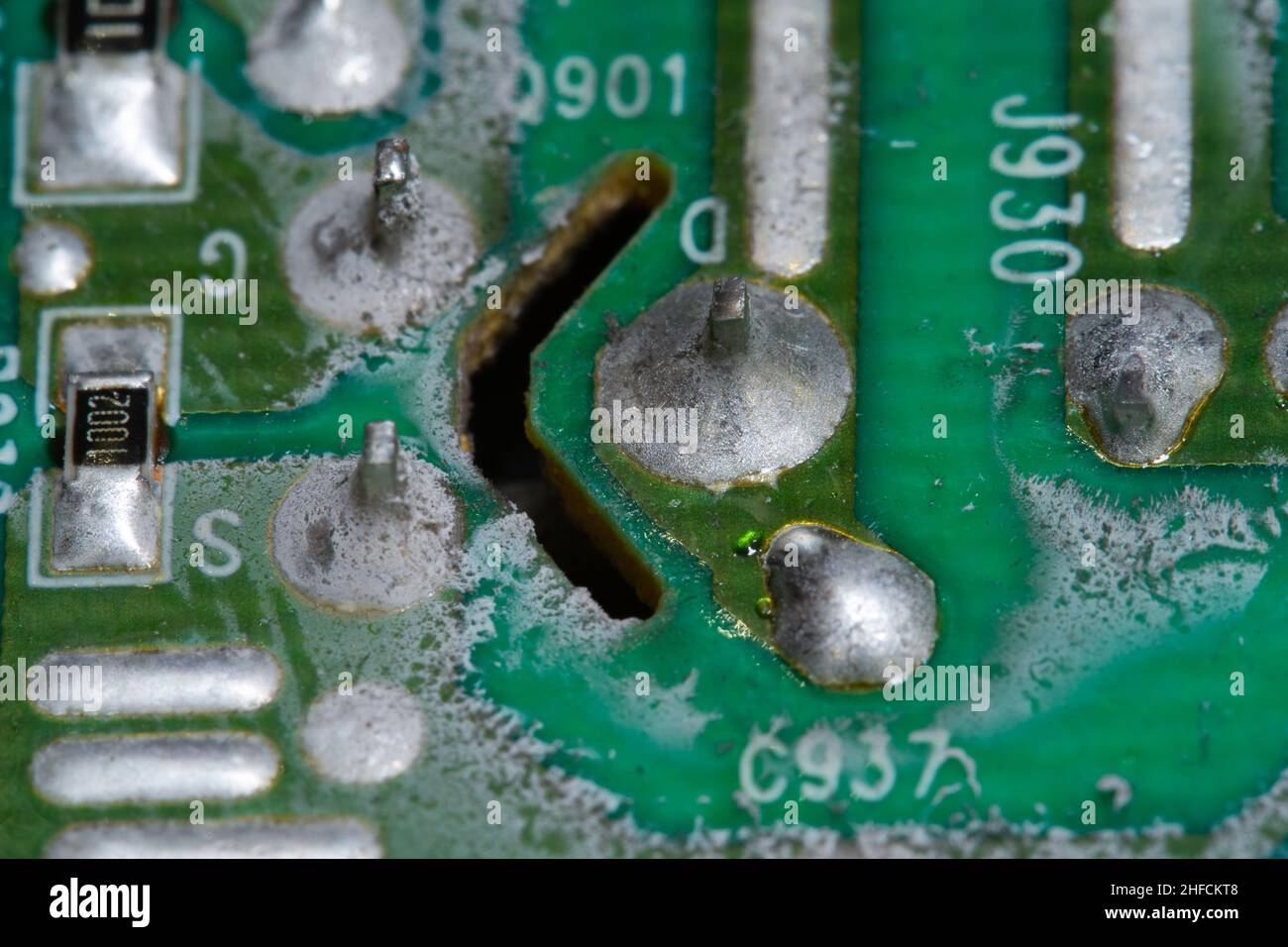

Another common issue is corroded traces. This often happens in humid environments or when the PCB has been exposed to moisture. The corrosion can weaken the traces and eventually lead to breaks. Cleaning the affected area with a specialized PCB cleaner or isopropyl alcohol and a soft brush can often remove the corrosion and restore conductivity. After cleaning, you might want to apply a conformal coating to protect the traces from future corrosion.

Remember to always disconnect the power source before attempting any repairs! This should be obvious, but it's worth repeating. Working on a live circuit is a recipe for disaster — both for you and the PCB. Safety first, always! A multi meter to probe the components and measure voltages is a huge help to pinpoint the issues.

Dealing with Burnt Components and Lifted Pads

3. The Hot Seat

Burnt components are a more serious issue. They indicate that something went seriously wrong, usually an overvoltage or overcurrent situation. Identifying the cause of the burnout is crucial before replacing the component, otherwise, you'll just end up with another burnt component. Check for shorts, faulty power supplies, or any other potential culprits. Replacing the burnt component without addressing the underlying issue is like putting a band-aid on a broken leg — it won't solve the problem.

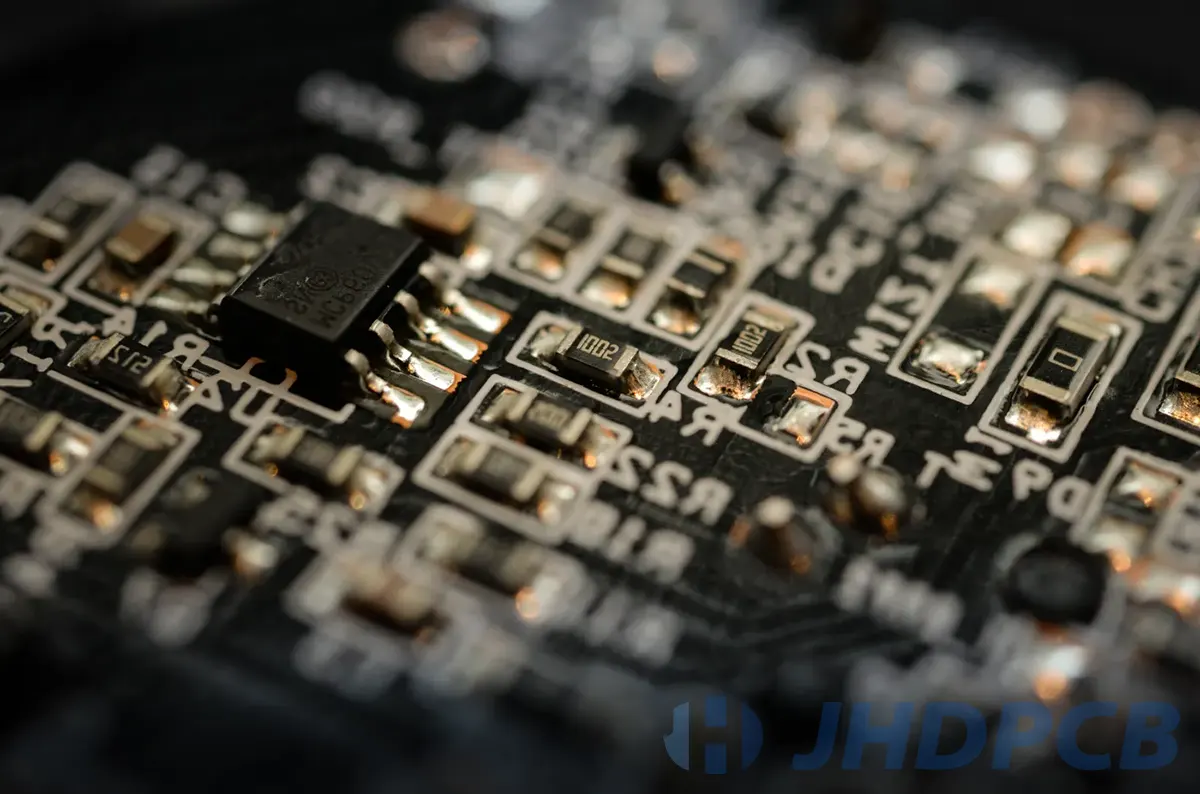

Replacing a burnt component typically involves desoldering the old component and soldering in a new one. This requires a good soldering iron, desoldering braid or a desoldering gun, and a steady hand. Make sure you use the correct replacement component with the same specifications as the original. Using a component with a different value or rating can cause further damage or malfunction.

One common cause for a component to burn is a faulty capacitor. These components are common in a PCB and have a limit. If the device or circuit is used heavily for years, there is a chance that some of the capacitor values will change, this can lead to overheating and eventually a component burnt. In that case, replacing ALL of the capacitors of the same type is better than replacing just 1.

When handling burnt components, take care to avoid inhaling any fumes or touching any residue. Some components may contain hazardous materials. Work in a well-ventilated area and wear gloves if necessary. Safety is paramount when dealing with potentially toxic substances.

How To Fix A Water Damaged Circuit Board At Nick Lopez Blog

Lifted Pads and Trace Repair Techniques

4. When the Pad Lifts Off

Lifted pads are another common problem. This happens when the copper pad that the component lead is soldered to becomes detached from the PCB. This is usually caused by overheating or excessive force during soldering or desoldering. Repairing a lifted pad requires a bit more finesse.

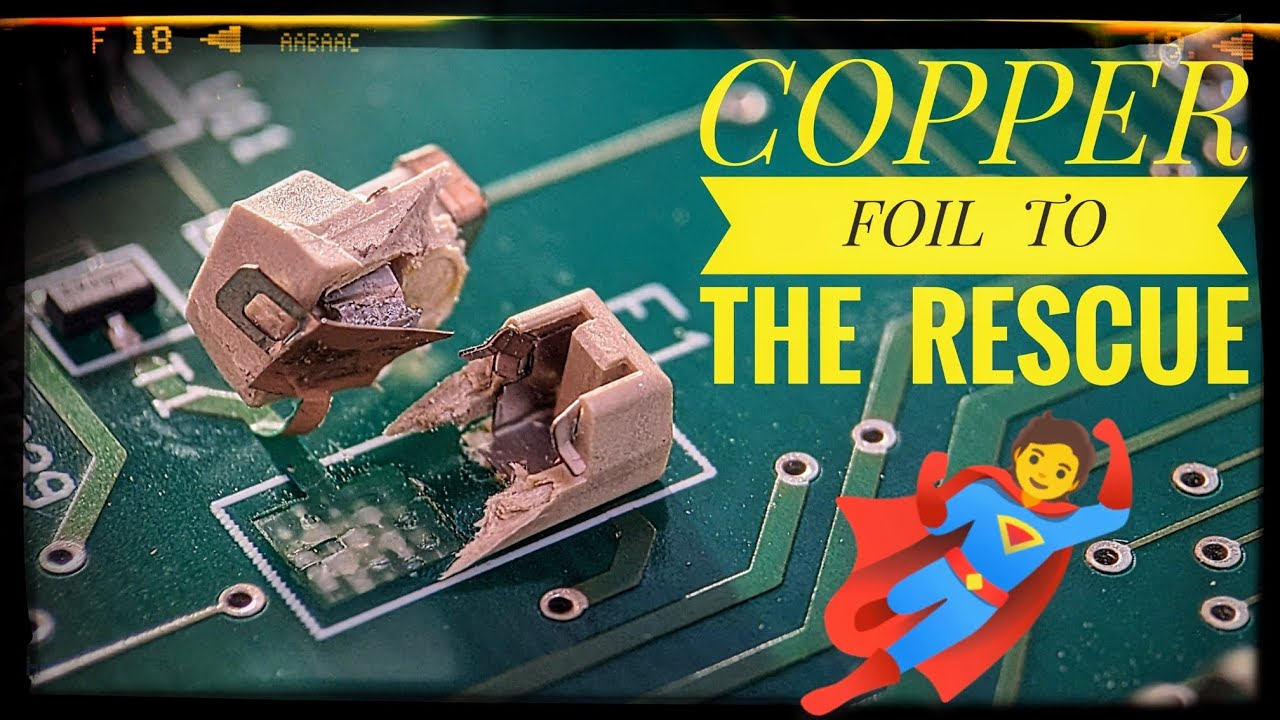

One approach is to carefully scrape away some of the solder mask around the lifted pad to expose some of the underlying copper trace. Then, you can solder the component lead directly to the exposed trace, creating a new connection. It may also require you to use a jumper wire to connect that trace to another via, pad or component.

Another option is to use a special PCB repair kit that includes replacement pads and adhesive. These kits allow you to glue a new pad onto the PCB and then solder the component lead to the new pad. This is a more robust solution, but it requires specialized materials and tools.

Before attempting to repair a lifted pad, make sure the surrounding area is clean and free of any debris. Use a sharp knife or scraper to carefully remove any loose material. This will ensure a good bond between the new pad and the PCB.

How To Repair Damaged PCB Pads / Traces Copper Soldering YouTube

Tools and Skills Needed for PCB Repair

5. Gearing Up for Success

To successfully fix a damaged PCB, you'll need a few essential tools. A good quality soldering iron with a fine tip is a must-have. You'll also need desoldering braid or a desoldering gun for removing components. A multimeter is essential for testing continuity and voltage. A magnifying glass or microscope will help you identify small cracks and other damage.

Other useful tools include wire cutters, wire strippers, tweezers, a PCB vise, and a good light source. A steady hand and good eyesight are also crucial. Practice makes perfect, so don't be afraid to experiment on scrap PCBs before tackling a real repair.

Having a schematic diagram of the PCB can be incredibly helpful. This will allow you to trace the circuit and identify the function of each component. If you don't have a schematic, you can sometimes find one online or create your own by reverse-engineering the circuit.

Don't underestimate the value of personal protective equipment (PPE). Wear safety glasses to protect your eyes from solder splatter and fumes. Use a fume extractor to remove harmful fumes from the air. And always wash your hands thoroughly after handling PCBs.

When to Call in the Professionals

6. Knowing Your Limits

Sometimes, despite your best efforts, a PCB repair is simply beyond your capabilities. If the damage is too extensive, the components are too small, or you lack the necessary tools or skills, it's best to call in the professionals. A professional PCB repair service has the expertise and equipment to handle even the most complex repairs.

They can also offer services such as BGA rework, which involves replacing Ball Grid Array (BGA) chips. This is a very specialized skill that requires expensive equipment and a lot of experience. Attempting to rework a BGA chip without the proper tools and training is almost guaranteed to result in further damage.

Consider the cost of professional repair versus the cost of replacement. If the PCB is in a crucial piece of equipment, it might be worth paying a professional to repair it, even if it's expensive. However, if the PCB is in a cheap gadget, it might be more cost-effective to simply replace the entire gadget.

Before hiring a professional PCB repair service, ask for references and check their online reviews. Make sure they have a good reputation and a proven track record of success. Don't be afraid to ask questions about their experience and their repair process. A reputable repair service will be happy to answer your questions and provide you with a detailed quote.